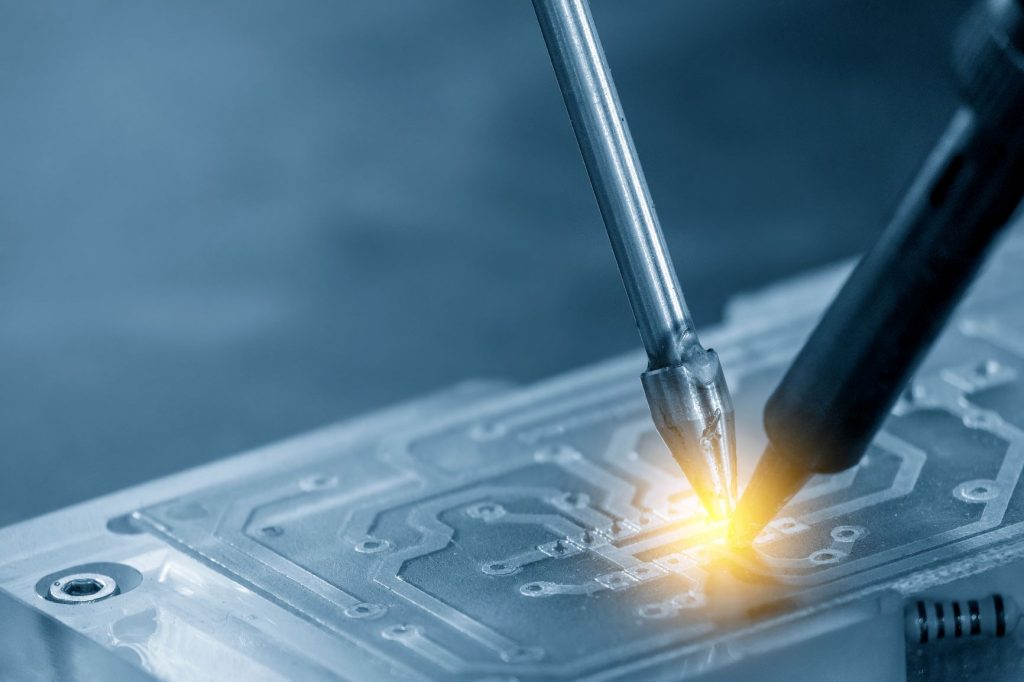

Laser Soldering

Selective Laser Soldering in Electronic Manufacturing

- Selective laser soldering is a process that utilizes a focused laser beam to precisely heat and melt solder to join electronic components on a circuit board.

- The process starts with the laser being aligned to the specific area where soldering is required. The laser beam is then directed onto the solder material, which heats up and melts, allowing the solder to flow around the components’ connections and create a secure electrical bond.

- The laser’s high precision enables targeted heating, reducing thermal stress on surrounding components and minimizing the risk of damage.

- The benefits of using a laser for soldering include the ability to work with very small and delicate components, often found in modern electronic devices.

- Lasers provide a high degree of control over the soldering process, resulting in consistent and repeatable outcomes. The non-contact nature of laser soldering reduces the likelihood of physical damage to the components.

- Selective laser soldering’s precise control and reduced thermal impact make it ideal for high-density circuit boards and advanced electronic assemblies.