Additive Manufacturing

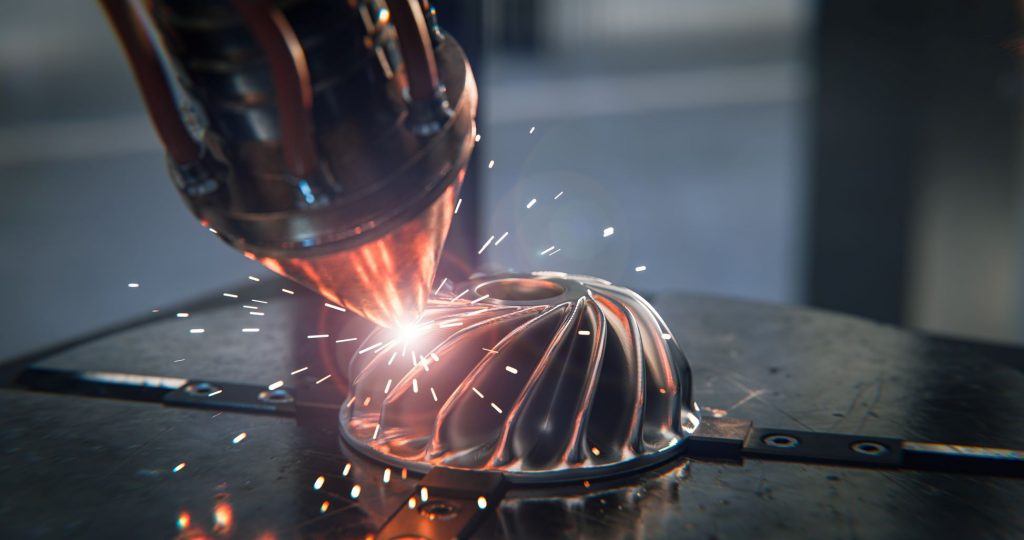

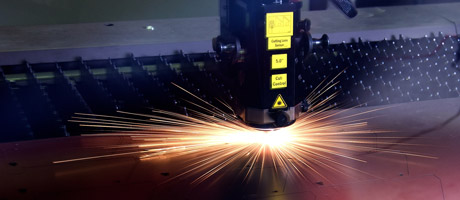

Selective Laser Sintering (SLS)

- Selective Laser Sintering (SLS) is an additive manufacturing process that uses a laser to sinter powdered material, typically plastic or metal, into a solid structure based on a digital model.

- The process begins with a thin layer of powder spread across a build platform.

- A laser beam then selectively fuses the powder by scanning cross-sections generated from the digital model onto the powder surface.

- After each layer is scanned, the platform lowers slightly, and a new layer of powder is spread on top. This process repeats layer by layer until the entire object is formed.

- The benefits of using a laser in SLS include high precision and the ability to create complex geometries that would be difficult or impossible with traditional manufacturing methods. Lasers allow for rapid production without the need for molds or tooling.

- Additionally, SLS can produce parts with excellent mechanical properties and fine details. This makes it suitable for prototyping as well as for creating functional end-use parts in industries such as aerospace, automotive, and medical devices.

- The ability to use a wide range of materials further enhances the versatility and application of SLS.