Plastic Welding

Plastic Welding

- Laser plastic welding is a process that joins two plastic components using laser energy. It typically involves a transparent upper layer and an absorptive lower layer.

- The laser beam passes through the transparent layer and is absorbed by the lower layer, causing it to melt. The heat generated at the interface creates a molten bond between the two layers.

- Pressure is applied to ensure intimate contact during the welding process.

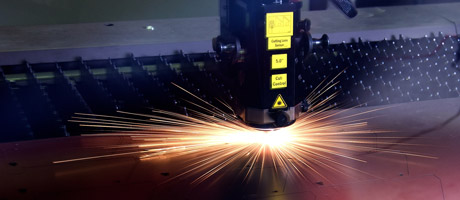

- Upon cooling, a strong, permanent joint is formed between the plastic parts.

- The benefits of using a laser include precise control over the welding process and the ability to create clean, high-quality joints without the need for additional adhesives or mechanical fasteners.